PRODUCTS WE PROVIDE

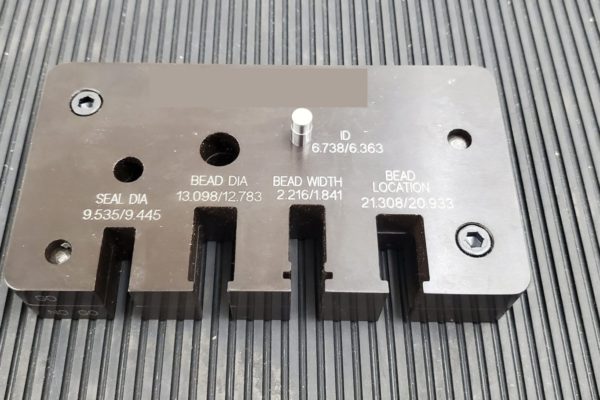

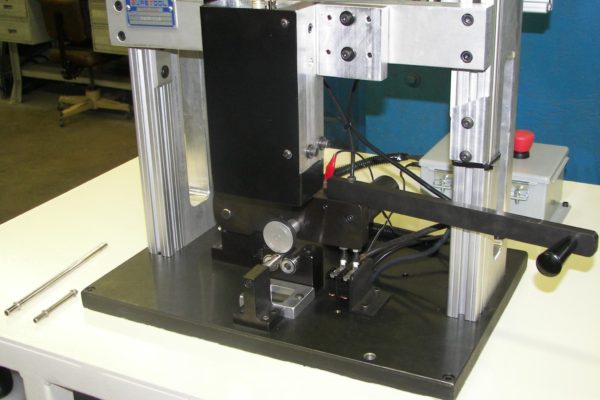

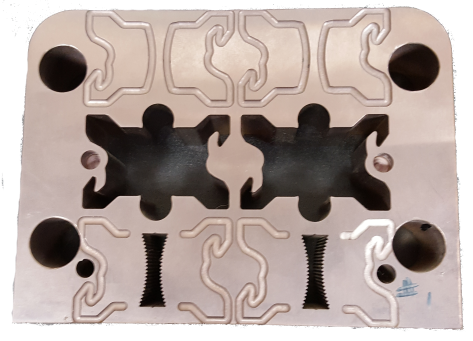

FUNCTIONAL GAGES

A functional gage is necessary when a low-cost means of a pass/fail (go / no go) check is required. Functional gages are often placed directly on the production floor and can be used by any employee with little training. We provide rugged gages that last in the field for years with little to no maintenance. We are experts in GD&T and can ensure that the gage is designed, built, and calibrated properly. Unless otherwise specified, we hold gage tolerances within 10% of part print tolerances.

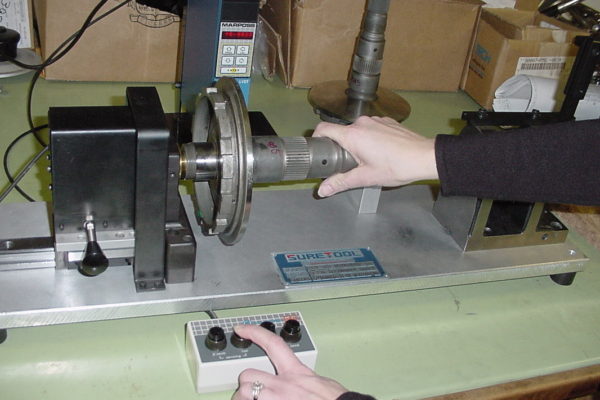

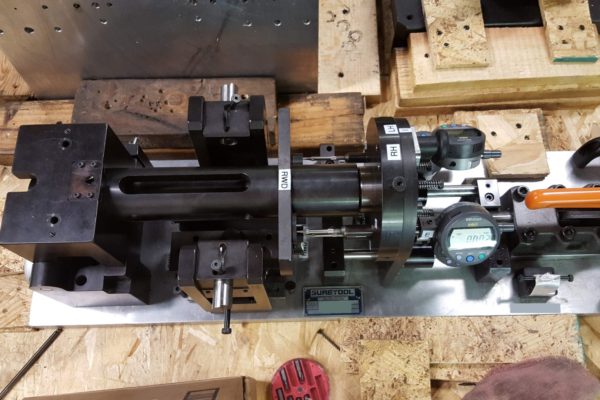

VARIABLE DATA GAGES

A variable data gage is used to collect measurement data for purposes of using statistical process control (SPC) to monitor and ensure the manufacturing process meets the required specifications. With variable measurement data, negative trending can be discovered prior to features being out of tolerance. This allows for tooling and process adjustments to bring dimensions closer to nominal values without producing scrap. Variable data gages are much quicker and cheaper than a CMM.

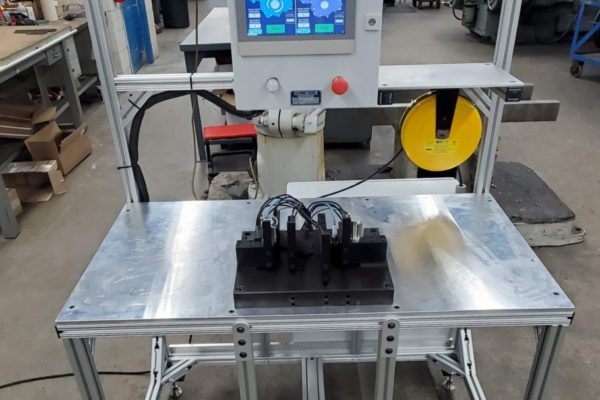

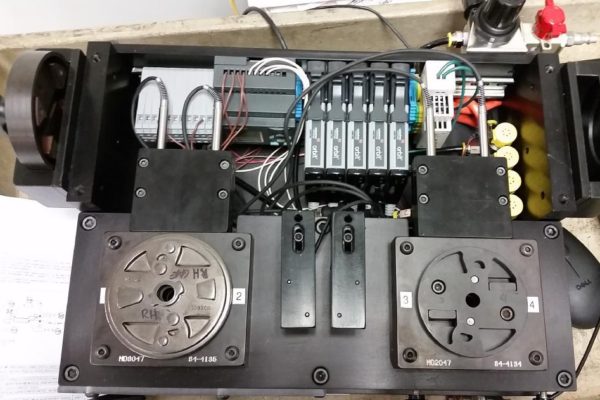

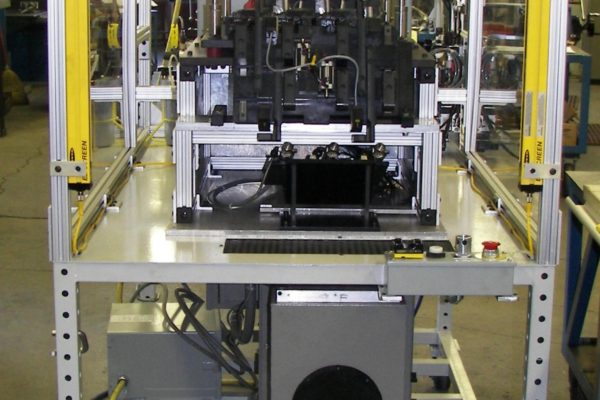

AUTOMATED GAGES

If 100% or a high volume of parts require inspection, then automated gaging should be considered. We have built gages which measure, mark, and sort parts based on different tolerance ranges. If a part is out of tolerance, then a reject chute is implemented. We can save measurement data as proof to your customers that all parts are within tolerance. We have vast experience with Allen Bradley and Siemens PLCs but are willing to work with others if your company has a preference.

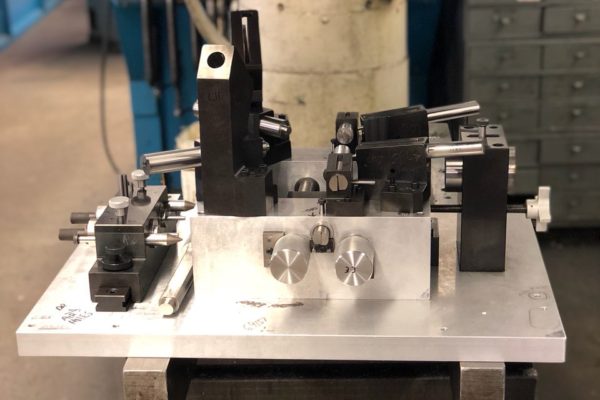

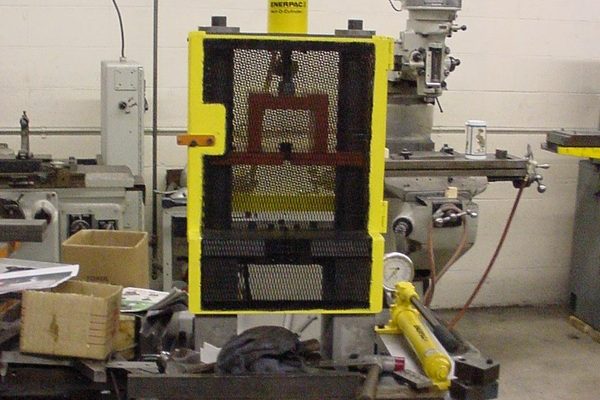

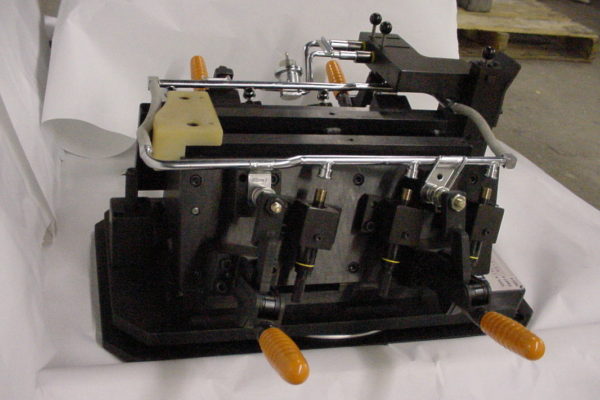

ASSEMBLY MACHINES

We also have the capability to design and build small-scale assembly machines which use pneumatics, servos, or a mechanical advantage to combine parts. We’re willing to take on any job we think we’re capable of completing. Having the design and manufacturing done under one roof reduces costs.

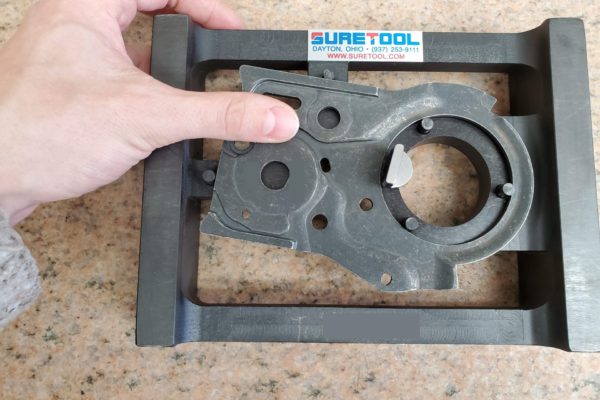

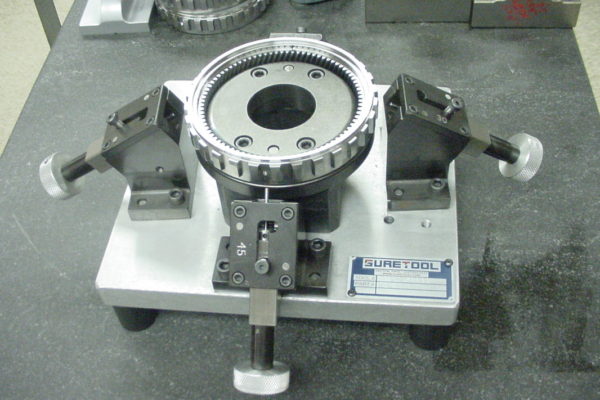

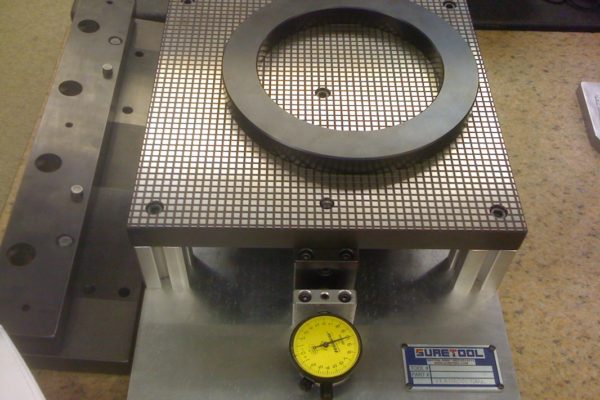

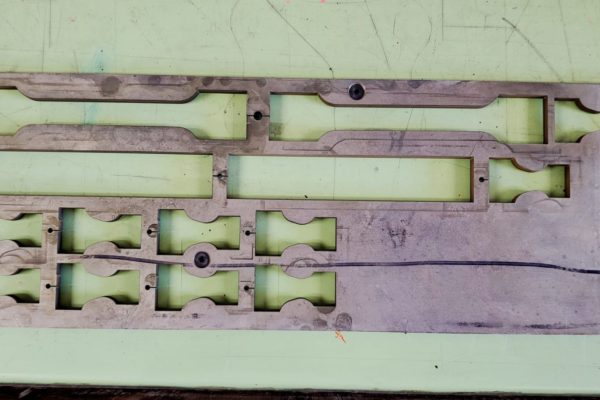

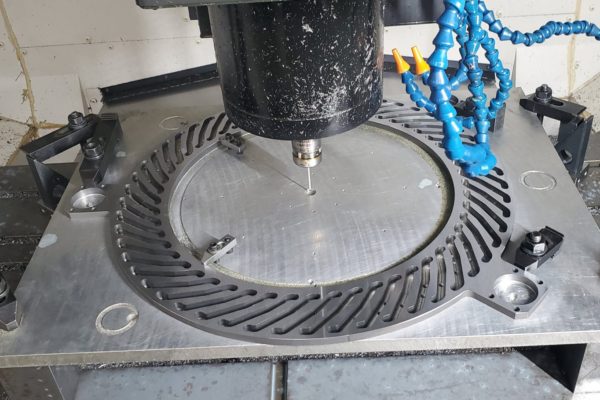

CMM FIXTURES

For quick parts setups on coordinate measuring machines, we provide custom CMM fixtures. Just let us know the features you need checked and the datums used to constrain the part, as well as CMM model and/or fixture plate design so we can ensure seamless integration.

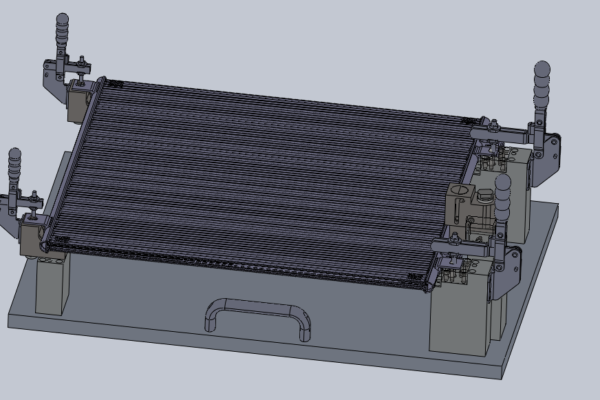

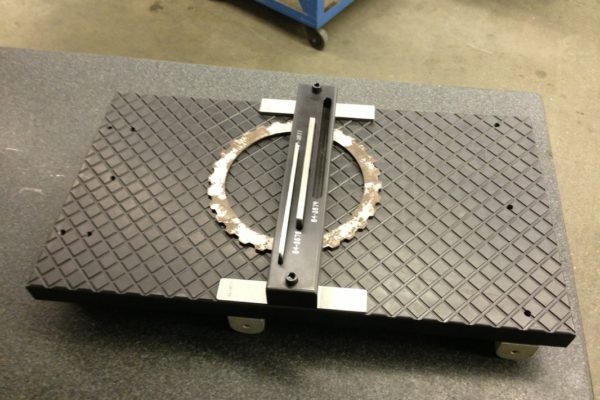

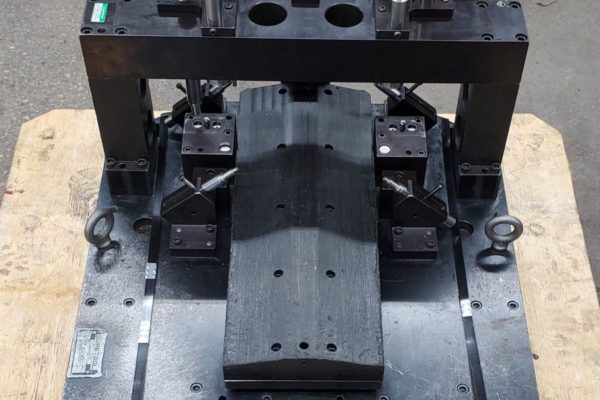

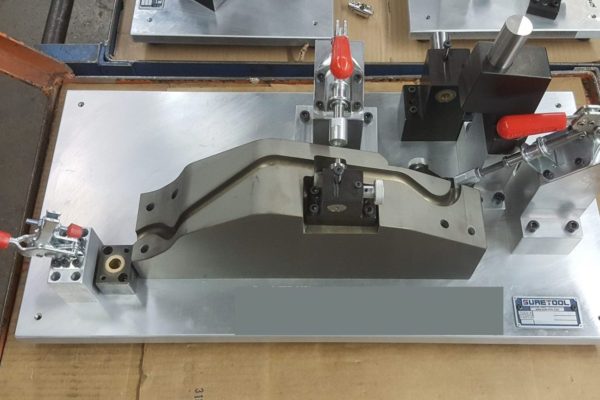

MACHINING FIXTURES

If standard off-the-shelf workholding fixtures aren’t suitable for your application, you might want to consider custom dedicated fixturing. We design all fixtures to properly constrain the part on the datum surfaces to meet GD&T requirements. We can also provide calibration on our fixtures so you can be confident they will support accurate machining.

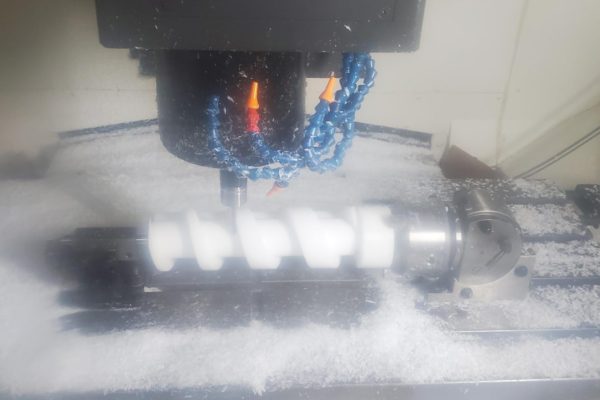

DETAILS

Details include any machined components (die details, tooling, etc.). Also known as print tooling. We’re familiar with a myriad different material selections, heat treatments, and coatings. Whether it’s A2, Inconel, carbide or plastic, we have yet to encounter a material we couldn’t process. We also provide suggestions to reduce detail costs if the price is too high (we’re experts in design for manufacturability).